Innovation at the Core of Peptide Manufacturing

Advanced peptide synthesis technologies are essential to meeting the growing demand for complex peptides in metabolic, oncological, and cosmetic therapeutics.

Achieving reliable and scalable production requires mastery of these multiple synthesis strategies. Each is optimized for molecular complexity, yield, and regulatory compliance.

As A Leading Global Peptide Solutions Provider, JYMed integrates the full spectrum of peptide synthesis technologies. This enables the delivery of high-quality, cost-effective, and cGMP-compliant manufacturing services from discovery through commercial production.

Solid-Phase Peptide Synthesis (SPPS): Precision and Efficiency

Solid-Phase Peptide Synthesis remains the backbone of modern peptide manufacturing, defined as a process in which a peptide anchored by its C-terminus to an insoluble polymer support (e.g., resin) is assembled by the successive addition of protected amino acids. Since the growing chain is bound to the insoluble support, excess reagents and soluble by-products can be easily removed by simple filtration, significantly simplifying purification.

At JYMed, SPPS is optimized through:

- Automated high-throughput synthesis systems that ensure high batch-to-batch consistency.

- Advanced resin and reagent selection for improved coupling efficiency and minimized side reactions.

- Controlled cleavage and purification protocols that maintain sequence integrity and maximize purity.

SPPS is particularly effective for medium-length and long peptides up to 60 amino acids. It is also well suited for complex sequences that require high levels of reproducibility and purity.

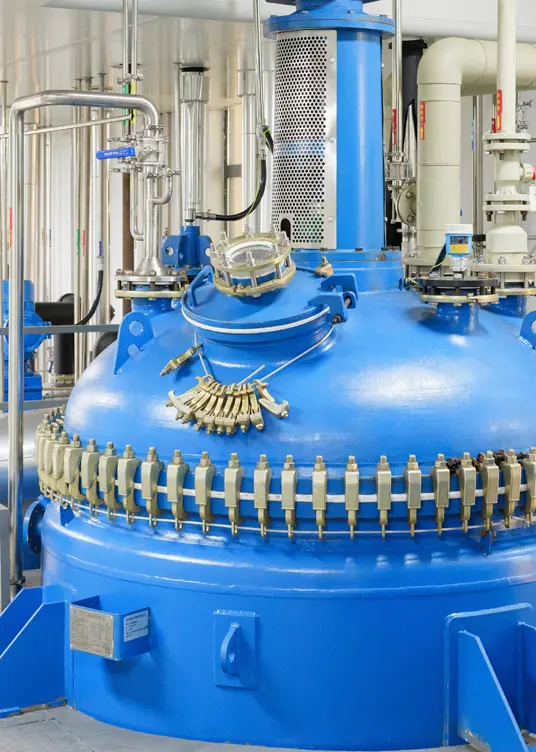

Liquid-Phase Peptide Synthesis (LPPS): Scalability and Cost Control

As one of the most scalable peptide synthesis technologies, Liquid-Phase Peptide Synthesis offers a flexible and efficient solution for large-scale manufacturing and shorter peptide chains.

Unlike SPPS, LPPS operates entirely in solution, allowing direct process monitoring and easier solvent recovery, which improves both cost efficiency and sustainability.

JYMed’s LPPS platform includes:

- Reactor volumes from 500 to 5 000 liters, enabling gram-to-ton scale production.

- Streamlined purification using Preparative HPLC and automated collection systems.

- Integration with SPPS workflows to balance cost, yield, and scalability.

LPPS is ideally suited for high-volume production of shorter peptides or simpler sequences where material efficiency and throughput are essential.

Hybrid and Liquid–Solid Phase Peptide Synthesis (L/SPPS): The Best of Both Worlds

For complex or long-chain peptides, JYMed applies Hybrid and Liquid–Solid Phase Peptide Synthesis strategies.

This combined approach merges the precision of SPPS for segment assembly with the flexibility of LPPS for fragment condensation and elongation.

The result is:

- Higher yield and purity for peptides that are difficult to assemble using only one platform.

- Improved scalability for sequences longer than 40 amino acids.

- Reduced reagent consumption and waste, enhancing both cost and environmental performance.

Hybrid synthesis allows to tailor each project to its technical and commercial requirements, providing consistent results from development to full-scale.

Minimum Protecting Group Strategy (MP-SPPS): Smarter Chemistry, Better Efficiency

Building on its hybrid synthesis expertise, JYMed applies the Minimum Protecting Group Strategy (MP-SPPS) to simplify peptide synthesis and improve control over every reaction stage. By using fewer types of protecting groups that can be independently removed (known as orthogonal protecting groups), this method streamlines synthesis steps, reduces reagent use, and prevents unwanted side reactions. Orthogonal protecting groups are chemical protections that can each be removed under specific, non-interfering conditions, allowing precise control of when every part of the molecule reacts.

Minimizing the number of these systems shortens reaction cycles, improves process stability, and ensures more predictable results.

This approach demonstrates JYMed’s commitment to efficient, sustainable, and high-quality peptide manufacturing.

Purification and Analytical Integration

Regardless of the specific peptide synthesis technologies used, purification and analytical validation are central to JYMed’s operations.

Each manufacturing stage is supported by advanced analytical and purification systems that ensure regulatory readiness and consistent quality.

Capabilities include:

- Preparative chromatography using Dynamic Axial Compression (DAC) columns ranging from 150 to 1 200 millimeters, which maintain stable packing density and enable high-purity peptide separation from laboratory to commercial scale.

- Two-dimensional LC online desalting for complex impurity separation and identification.

- Advanced techniques (LC-MS/MS, GC/MS, and UPLC) for structure confirmation and purity assurance.

- Real-time analytical feedback systems that guide process optimization and quality control.

This seamless integration of analytical development guarantees that every peptide produced meets global cGMP standards for purity, identity, and regulatory compliance.

Technology That Scales with Science

JYMed’s synthesis platforms — SPPS, LPPS, Hybrid, and MP-SPPS — combine flexibility, scalability, and precision to support peptide development from early-stage research to commercial manufacturing.

Through continuous process innovation, automation, and analytical excellence, JYMed enables pharmaceutical and biotech partners worldwide to advance their peptide programs efficiently, sustainably, and confidently.

JYMed Technology Co., Ltd.

A Leading Global Peptide Solutions Provider

0 Comments